Project summary

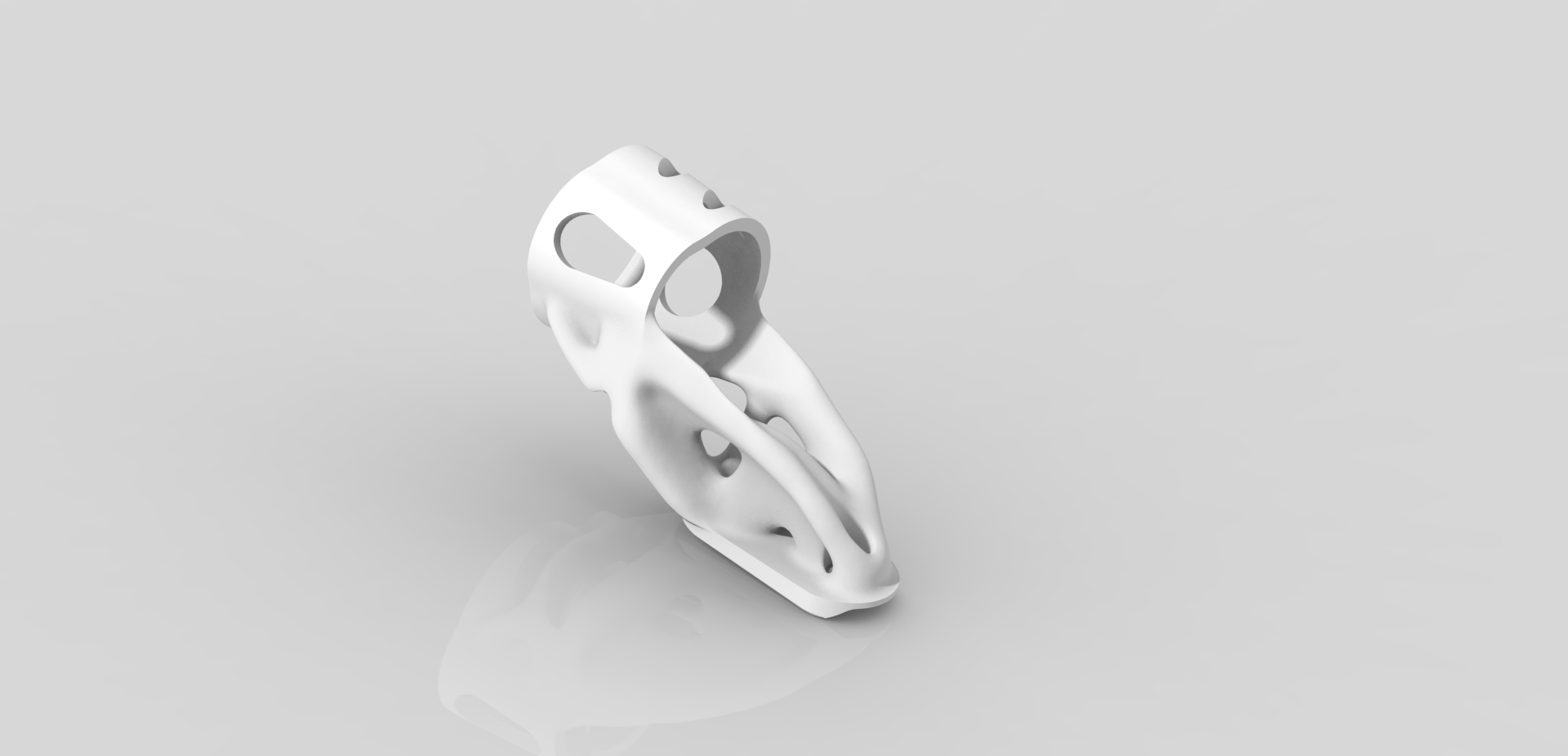

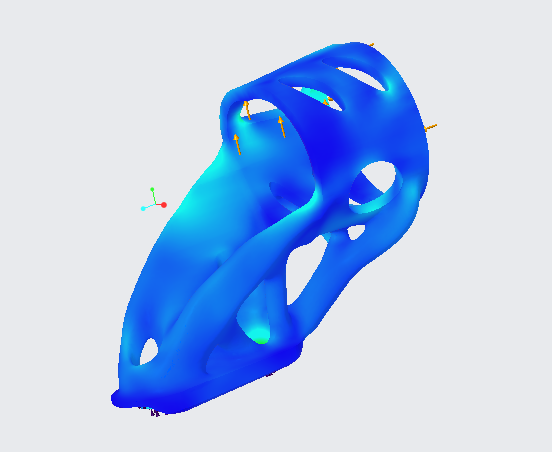

This part integrates the locking plate of a metal detector handle with a holder for a smaller “pinpointer”-type detector. Generative Design application was used in constructing the final geometry. Part was 3D-printed and assembled to the detector replacing the original locking plate.

Why?

Project got started when a family member requested a 3D-printed locking plate for a metal detector. As this specific part must be ordered online and is quite expensive, printing the part made sense. Original piece from a second detector was photographed and a CAD-model was created based on these images. Final result turned out to be quite a good fit.

Modifying the design

Some time later, during a discussion about metal detector accessories, a request for a 3D-printed pinpointer holder was made. After considering multiple designs, a decision was made to use the existing locking plate slot as an attachment point. This would negate the need for any external rails or other attachment methods.

The existing locking plate model was modified and used as a base for building the holder model. Pinpointer was measured with vernier caliper, and some prototypes were printed to test the fit. A small groove was added to one side for a more secure attachment, and cutouts were added to surfaces with contact to the pointer in order to prevent dirt from clogging the holder during use. Finalized design was then optimized with Creo’s generative design extension by reducing the volume by 50 % while maximizing rigidity.

Manufacturing and the final result

Finalized model was exported as a STL-file. Cura slicer software was used to generate a Gcode file for a FDM-style 3D-printer. Part was printed from PLA with 50% infill, further reducing the weight. Final result was a good fit, but further testing will be done after ground unfreezes this spring.