Project summary

This project consisted of designing a handle around a set of given measurements, and then 3D-printing it. The resulting part fit nicely, and according to the feedback was ergonomically superior to the original part.

Why?

This project got started when one of my friends managed to somehow break a refrigerator door handle. As replacement parts for this particular model were difficult to come by, we decided that designing and 3D-printing a new one would make for an interesting project!

The Design Process

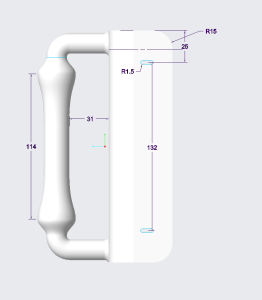

The design started from sketching different concepts for the handle shape. Special focus was placed on ensuring that the handle would be comfortable to use. The idea was to not even attempt to replicate the original part, but rather to utilize the freedom given by 3D-printing to create a completely custom handle. Once a suitable shape was established, measurements needed to be taken from the door to establish locations for the attachment screws, as well as geometry of the attachment plate. After receiving the measurements, I started to model the handle using a CAD-software. The modelling process itself was split into two parts: The attachment plate and the handle itself. The part did not require any complex modeling techniques, and was created relatively quickly. To verify the dimensions, I sent the annotated screenshots of the model to my friend for feedback.

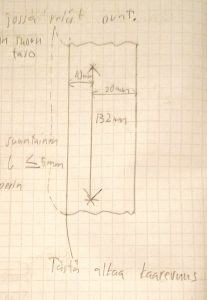

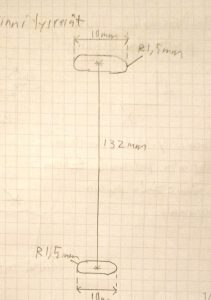

Figures 2 and 3: Original measurement drawings.

Figure 4: One of the annotated screenshots that was sent to verify the dimensions

Manufacturing and final result

The part was printed from PLA with 50% infill. Outer wall line count was set to 3 in order to reinforce the attachment plate.