Palm oil must become more productive in order to be more sustainable.

Even though palm oil is already the most productive source of vegetable oils – in terms of tons of oil per hectare – increasing productivity is critical for protecting forests and biodiversity. This is because palm oil production growth is largely due to an increase in planted area at the expense of other land uses and biodiverse ecosystems.

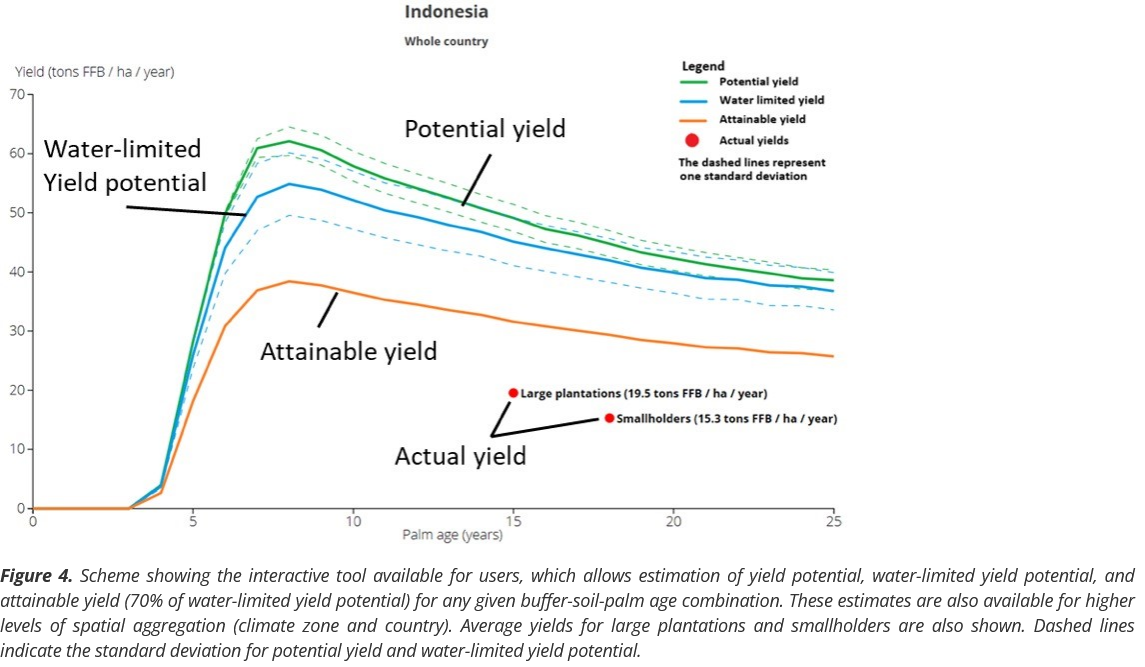

Of course, improved hybrid cultivars are important too, and so are developments in fertilization and upkeep. However those have not been true drivers of productivity growth for a long time. Certainly many plantations could do with more work and better management, but, using the technical term, a yield-gap exists between what is possible in research and what is achieved in practice. Back in the early 2000’s research plantations in Malaysia were achieving yields of 33 tons of FFB per hectare – two decades ago! Today the best in the industry, United Plantations, gets close with 28.9 t/FFB/ha, but average production in Malaysia in 2021 was 15.5 t/FFB/ha. Sure 2021 was difficult in terms of labour, covid and supplies, but when productivity in the most developed palm oil sector in the world hasn’t been over 18 t/FFB/ha since 2015, something is wrong. Oh and, UP’s numbers are also 2021 so what gives?

Lets be direct: Poor management, poor use of labour, poor employment of capital. And yes; poor mechanisation.

UP historically is very mechanised; their older plantations have narrow gauge railways dating back to the middle of the last century if not earlier. Capital was used to lower production costs over the longer term (meaning there’s more leeway to ensure labour availability now). UP is also a significant user of powered harvesting tools. Everyone else is barely out of the trial phase. What this means is that UP manages to be one of the most sustainable vegetable oil producers in the world – exactly what all plantations in Malaysia should be.

I used the word “mechanised” deliberately. I know it is not fashionable; palm oil tech is all about “automation” now. That and drones. I’ll write a post about that later.

Now back to the main point: the sector has met increasing demand by expansion, rather than intensification. This I think is sub-optimal. It has exposed the sector to a legitimacy crisis in many markets, it has caused significant environmental damage and social problems.

What I think is a path forward is a combination of two things; far stricter conditions for planted area expansion and investment that increases productivity. In effect I would want to see an almost complete stop to planted area growth in Malaysia and Indonesia, caused partly by regulation, but mostly by it becoming cheaper and more acceptable to intensify production instead.

I would like to see NGO’s and the RSPO take a stronger stance on productivity improvements. Indeed, to expect best management practices just as much as no-deforestation. I think one of the best ways to reduce and in-fact stop the negative impact on forests and ecosystems is to make existing plantations as productive as possible and meet demand growth through better productivity.

PS. have a look at the yield gap atlas: https://www.yieldgap.org/

Malaysia isn’t on yet, but Indonesian Oil Palm yields are, and the news isn’t good: